The High-Stakes Puzzle of Electronics Remanufacturing

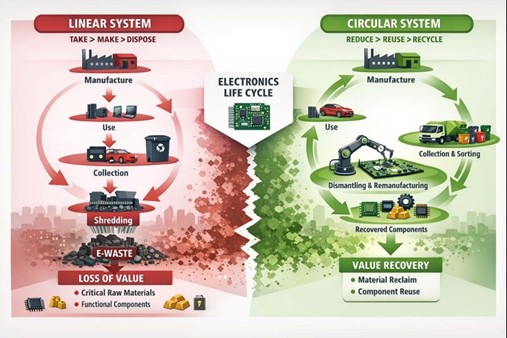

Electronics sit at the core of our modern systems, yet the way they are treated at the end of life remains rudimentary. In the EU, billions of tons of waste are generated every year, and the combination of labor intensity and wide variations in product condition puts real pressure on circular economy ambitions [1]. The challenge is straightforward: these components are high in value and technically sophisticated, accounting for up to 35% of a vehicle’s total cost, while at the same time being physically small and highly complex [2]. They are typically designed for seamless integration, durability, and low assembly cost—choices that make disassembly difficult. Unlike a flat tire, it is rarely possible to see whether a microscopic circuit has failed, and the industry still lacks structured frameworks to address this complexity in a consistent and precise way [3]. As manual inspection rarely delivers a clear financial return, millions of high-value automotive electronic components are shredded each year. The result is a linear system that limits value retention and leads to the loss of critical raw materials [4].

“Can we stop destroying value? We want to ‘see’ inside a device and disassemble it with the same precision as for assembly!”

Digital Product Passports (DPPs) are being positioned in EU policy as a key enabler of circular economy strategies, with the potential to support life‑cycle data continuity, including material composition, maintenance history, reparability, and end‑of‑life dispositions [5].

ROB4GREEN is developing AI-driven collaborative robotic systems that reason and adapt to various strategies for processing products after their first life. By combining data and knowledge, we turn opaque, manual decision-making into explicit, scalable, and auditable workflows .

ROB4GREEN’s AI‑based platform turns the invisible visible, providing the intelligence needed to rescue high‑value components from the scrap heap.

ROB4GREEN’s AI-based platform turns the invisible visible, providing the intelligence needed to rescue high-value components from the scrap heap.

At our Veszprem electronics cards manufacturing site, we pilot a novel human-robot collaborative line for the disassembly and retrieval of electronic components. This happens under the supervision of the Electronics Circularity Lab in Nevers, France. The technical setup features a low-payload collaborative robot—chosen for the dexterity required in electronics—working in tandem with human experts [6].

Key technological pillars of our December 2025 progress include:

Multispectral AI Inspection: Since defects are often hidden, we use multispectral AI-driven inspection to identify component variants and detect internal damage without destructive opening [7].

Neuro-symbolic Decision Support: Leveraging the PyReason framework, our system integrates symbolic production rules with data from Digital Product Passports (DPPs). This allows the system to reason whether a component should be repaired, reused, or sent for material recovery.

Automated De-soldering & Precision Handling: Once marked for rescue, the robot performs high-precision de-soldering and sorting of components into eight distinct families.

Integration and Benefits

This system integrates into the overall workflow by aligning heterogeneous data via an ontology, transforming natural language rules into formal logic for machine interpretability [8]. The expected benefits include a 25% reduction in raw material costs, a 15% reduction in waste disposal, and significantly reduced training time as employees are supported by guided, system-generated actions.

“Automated component detection now exceeds 90% accuracy, cutting manual selection time and transforming discarded circuit boards into reliable, high-quality assets.”

By reclaiming the critical raw materials locked inside our waste, we ensure European industrial autonomy. This transition to automated, selective disassembly is a crucial step in achieving the objectives of the Green Deal and a truly sustainable electronics lifecycle.

References (Format IEEE)

[1] M. Kühn et al., “Digital Product Passport Design Supporting the Circular Economy Based on the Asset Administration Shell,” Sustainability, vol. 17, no. 3, p. 969, Mar. 2025, doi:10.3390/su17030969.

[2] S. B. Hybel, “Design for Disassembly: An analytical method,” Journal, 2025.

[3] Z. Zhang, et al., “A literature review of digital product passport systems,” Elsevier, 2016.

[4] A. Priyono et al., “Disassembly for Remanufacturing,” 2016, pp. (PDF).

[5] “The Strategic Benefits and Incentives for Companies to Implement the Digital Product Passport,” Journal of Circular Economy, Feb. 2025.

[6] S. Shahbazi et al., “Product Design for Automated Remanufacturing—A Case Study,” Sustainability, vol. 13, no. 16, 2021.

[7] Multispectral imaging and AI for non‑destructive inspection, domain literature (emerging; see general literature). (Research background references.

[8] Ontology‑based data integration for circularity and remanufacturing workflows, domain practice. (Emerging consensus from technical literature).

Dr. Kevin Boissié, Valeo

Dr. Kevin Boissié, Valeo, Senior Expert in Obsolescence Engineering. Dr. Kevin Boissié is a senior researcher at Valeo Nevers, focusing on risk management tools for electronics lifecycles and AI-driven remanufacturing strategies.